1. ʻO nā pono a me nā pōʻino o ka mīkini welding laser a me kāna kiko noi

ʻO ka mīkini wili laser kahi ʻano hana wili hou, me ka ikaika haʻahaʻa haʻahaʻa, kahi ākea i hoʻopili ʻia i ka wela a me nā pono ʻē aʻe he nui, i ka mākeke hana metala o kēia manawa, ua hoʻohana nui ʻia ka welding laser, ua hoʻohana lōʻihi ʻia ma nā ʻano āpau o ke ola. , e like me: ke kīʻaha insulation metala, ʻoihana kelepona kelepona, ʻoihana lapaʻau, ʻoihana kaʻa a me nā ʻoihana ʻē aʻe he nui.

01 ʻO nā pono o ka mīkini welding laser

Ke hoʻohālikelike ʻia me ka ʻenehana kuʻuna kuʻuna, ʻo ka ʻenehana welding laser ʻaʻole i hoʻopili ʻia, ʻaʻole pono ke kaʻina hana i ke kaomi, he wikiwiki wiliwili wikiwiki, ikaika kiʻekiʻe, hohonu, liʻiliʻi liʻiliʻi, liʻiliʻi weld seam, wahi liʻiliʻi wela, a me ka mea hana. liʻiliʻi ka deformation, ʻoi aku ka liʻiliʻi o ka hana hoʻoili ʻana i ka hahai ʻana, e hōʻemi i ka puka manual, kiʻekiʻe kiʻekiʻe, ʻoi aku ka palekana a me nā pono ʻē aʻe.

Hiki ke hoʻohana ʻia ka ʻenehana hoʻoheheʻe laser e wili i nā mea refractory e like me nā metala hoʻoheheʻe kiʻekiʻe, a me nā mea non-metallic e like me nā ceramics a me nā aniani kūlohelohe, me nā hopena kuʻi maikaʻi ma nā mea i hoʻohālikelike ʻia a me ka maʻalahi. No ka wiliwili ʻana i nā ʻāpana hiki ʻole ke loaʻa, hoʻokō ʻia ka hoʻoili ʻana i ka wiliwili ʻole. Hiki ke hoʻokaʻawale ʻia ke kukuna laser i ka manawa a me ka ikaika, e hiki ai i ka hoʻoili like ʻana o nā kukuna he nui, e hāʻawi ana i nā kūlana no ka hoʻopili pololei ʻana.

02 Nā mea e hoʻomaopopo ai i ka hoʻohana ʻana i nā mīkini welding laser

Pono e hoʻomaopopo ʻia nā ʻaoʻao aʻe i ka wā e hoʻohana ai i ka mīkini welding laser

(a) Pono pono ke kūlana o ka ʻāpana welded, e hōʻoia ana aia i loko o ka manaʻo o ka kukuna laser.

(b) Ke koi ʻia ka ʻāpana welded i ka hoʻohana ʻana i kahi mea paʻa, pono e hōʻoia i ke kūlana hope o ka ʻāpana welded pono e hoʻopili ʻia me ka weld point kahi e hopena ai ka kukuna laser.

(c) Ua kaupalena ʻia ka mānoanoa weldable kiʻekiʻe, ʻo ke komo ʻana o nā mea hana me nā mānoanoa ma mua o 19mm i ka laina hana pono e kūkākūkā me ka mea hana e hāʻawi i ke kākoʻo ʻenehana ʻoihana.

03 Nā noi o nā mīkini welding laser

1. ʻOihana Battery

Hoʻohana ʻia ke kelepona kelepona a me ka hapa nui o nā huahana code o ka pākaukau i ka welding laser.

2. 'Oihana lumi kuke lumi lumi

ʻOi aku ka maikaʻi o ka hoʻoheheʻe ʻia ʻana o ka laser, no laila i loko o ka hale ʻauʻau kiʻekiʻe kiʻekiʻe o ke kila kila nā huahana laser marking laser welding he nui nā noi. E like me: nā lima lima, nā kīʻaha, nā pahi ʻoki ʻoki ʻoki a me ka hapa nui o ke ala me ka hōʻailona laser o ka hana ʻana i ka LOGO hui, nā ipu uila kiʻekiʻe a me nā sila ʻē aʻe e hoʻohana i ka welding laser e hoʻopau ai. ʻO nā lako kīhini, nā kīʻaha papaʻaina hui kuʻi kuʻekuʻe kuʻekuʻe kuʻekuʻe kuʻi, wehe ʻia ka hana ʻana a me ka hoʻoponopono ʻana a hoʻololi a hoʻololi i ke kaʻina hana.

3. Nā huahana kikohoʻe, kelepona kelepona, ʻoihana kamepiula

Laser kaʻina hana ma muli o ka precision hana 'enehana, i loko o ka kikohoʻe, kelepona, kamepiula kahua noi oi kaulana e like me: kelepona hele lima, MP4, MP3 shell laser welding, laina laina, laptop lolouila, fiber optic mea wahi wiliwili, kamepiula chassis hoʻohui kuʻihao. .

4. ʻOihana mīkini ʻenehana

Hoʻomaʻemaʻe lako wiliwili, electromechanical ʻāpana wiliwili, hoʻoponopono i nā mea hoʻohui.

5. Electronics, ʻoihana uila

No ka mea ʻo ka hoʻoili ʻana i ka laser he ʻano hana hoʻopili ʻole, ʻaʻole ia e hana i ka extrusion mechanical a i ʻole ke koʻikoʻi mechanical, no laila e hoʻokō pono ai i nā koi o ka ʻoihana uila. E like me: transformers, inductors, connectors, terminals, fiber optic connectors, sensors, transformers, switches, cell phone batteries, microelectronic components, integrated circuit leads and other welding.

6. ʻoihana mea hoʻonani

Ma muli o ka maikaʻi loa o ka hoʻoili ʻana i ka laser, kūpono ia no nā huahana makamae a liʻiliʻi i ka ʻoihana waiwai. Ma muli o ka maikaʻi loa o ka kukuna laser, ua hoʻonui ʻia e ka microscope e hoʻonui i nā ʻāpana liʻiliʻi o nā mea nani a ʻike i ka wili pololei. ʻO ka laser spot welder he mea pono ia no ka hoʻopili ʻana i nā kaulahao nani a me ka inlay o nā pōhaku.

7. Paʻa paʻa, mea hana, ʻoihana mea kani

Mea hana, sensor, lumi kuke, tableware hui kuʻihao butt welding, wehe a hoʻopololei hana a hoʻoponopono a hoʻololi i ka poʻi i ka wā e hoʻohana ai. ʻO ka hoʻoheheʻe ʻia ʻana o ke kila kila, hoʻoheheʻe ʻia ma ka hoʻopili ʻana o ke kumu mika.

8. ʻOihana kaʻa kaʻa uila

ʻO ka hana laser no ka hoʻopili ʻole ʻana, ʻaʻohe haumia i ka huahana, kiʻekiʻe ka wikiwiki, ʻoi aku ka maikaʻi no nā pono o ke kaʻina hana o nā mea kūʻai aku kaʻa kaʻa kiʻekiʻe, e like me ka welding dial automotive, valve welding, piston ring welding, automotive cylinder gasket welding, paipu hoʻopau, kānana kuʻi, kuʻihao o ka automotive palekana kinoea generator. ʻO ka ʻoki ʻana i nā ʻāpana i ka hoʻāʻo ʻana a me ka pae liʻiliʻi o ka hana ʻana o nā kaʻa, a me ka hoʻopaʻa ʻana i nā pihi no nā kaʻa uila.

9. ʻOihana kukui uila

Hoʻohana nui ʻia ka hoʻoili ʻana i ka laser i ka hana ʻana o nā cell solar: e like me ka ʻoki ʻoki ʻana i ka ʻokiʻoki ʻana i ka lā silicon wafer laser, ka hoʻoheheʻe ʻana i ka pā wela wela. E hoʻohana nui ʻia ka hoʻohana ʻana i ka laser, ma ke ʻano he ʻano hoʻonaninani kūlohelohe a maikaʻi hoʻi i ka wā e hiki mai ana.

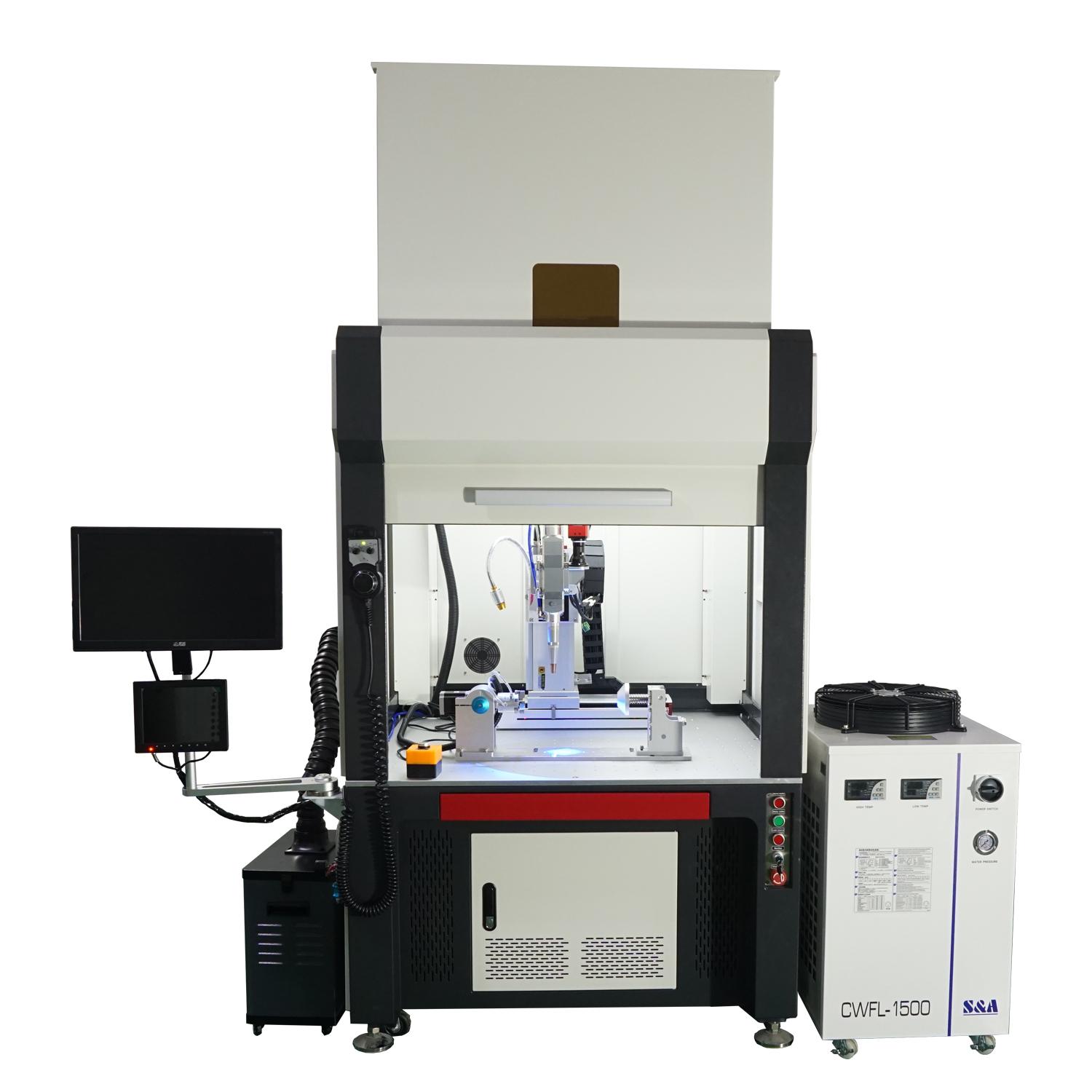

2.He aha ka ʻenehana hoʻoheheʻe ʻana i ka mīkini hoʻoheheʻe ʻo Platform?

ʻO ka mīkini hoʻoheheʻe laser maʻemaʻe ʻo Platform kahi mīkini wiliwī maʻalahi e hoʻohana ana i nā pulse laser kiʻekiʻe e hoʻomaʻamaʻa i nā mea i loko o kahi wahi liʻiliʻi. Hoʻolaha ʻia ka ikehu o ka radiation laser ma o ka lawe ʻana i ka wela i loko o ka mea a hoʻoheheʻe ʻia ka mea e hana i kahi wai hoʻoheheʻe kikoʻī. Hoʻohana nui ʻia ia no ka hoʻopili ʻana i nā mea ʻili lahilahi a me nā ʻāpana kikoʻī, a hiki ke hoʻomaopopo i ka wiliwili uila, butt welding, lap welding, sila welding, etc. porosity, mana pololei, kūlana kiʻekiʻe, a me ka automation maʻalahi.

3.He aha ka mīkini hoʻoheheʻe laser paʻa lima?

E like me ka inoa e hōʻike nei, ʻo ka mīkini wili laser manual kahi ʻano o nā mea hana wili e pono ai ka hana lima. Hiki i kēia mea wiliwili ke hana i ka welding laser ma nā mea hana lōʻihi a nui. I ka wā e wili ai, liʻiliʻi ka wahi i hoʻopili ʻia me ka wela a ʻaʻole ia e hana i ka deformation, ʻeleʻele a me nā kaha ma ke kua o ka mea hana. He nui ka hohonu o ka welding, paʻa ka hoʻoheheʻe ʻana, lawa ka hoʻoheheʻe ʻana, ʻaʻohe pilikia i loko o ka wai hoʻoheheʻe kahi e hui ai ka projection o ka mea hoʻoheheʻe me ka substrate.

4.He aha ka ʻokoʻa ma waena o ka mīkini hoʻoheheʻe laser a me ka mīkini hoʻopaʻa lima lima?

ʻO nā mīkini hoʻoheheʻe laser aunoa e hoʻopaʻa ʻia e like me kahi papahana i hoʻonohonoho ʻia ma hope o ka hoʻonohonoho ʻia ʻana i ka polokalamu; ʻO nā mīkini hoʻoheheʻe laser manual, i ʻike ʻia ʻo ka welding spot, hoʻohana ʻia e nā mea hoʻohana i ka wā e hoʻohana ai i nā mea wili laser ma o ka hoʻonui kiʻekiʻe i ka pale.

Hana ʻia ka wiliwili wahi ʻike ma ka lima a hana maʻamau ʻia e nā mea hana laser e hoʻokō i nā pono o ka mea hoʻohana. He liʻiliʻi nā mea hana i loaʻa nā mea waiwai. Inā loaʻa nā mea waiwai, hāʻawi ʻia i ka mea hoʻohana ma ke ʻano he prototype a i ʻole hōʻike hōʻoia. ʻO ka mea nui aku, ʻo ka mana a me nā hiʻohiʻona o nā mea hana welding e hoʻoholo ʻia ma o ke kūkākūkā ʻana me ka mea hoʻohana, a pono mākou e hāʻawi i ka mea hoʻohana i kahi huahana lako waiwai e pili ana i ke kumu kūʻai. I ka hihia hea ʻoi aku ka maikaʻi o ka hoʻohana ʻana i ka mīkini welding laser manual, ke hoʻohālikelike ʻia me ka mīkini wili laser piha piha, ʻaʻole wale ke kumu kūʻai kiʻekiʻe, akā kiʻekiʻe ke kumukūʻai mālama. ʻO ka ʻoi aku ka pololei o kekahi mea ʻoi aku ka nui o ka mālama ʻana a ʻoi aku ka kiʻekiʻe o ke kumukūʻai. Eia kekahi, ʻoi aku ka nui o ka welding laser piha i ka CNC automation o ka papa hana, e koi ana i ka hana kiʻekiʻe a me ka versatility o ka papa hana, akā i ka hoʻomaʻamaʻa, ʻaʻole kēia he panacea, a ʻaʻole hiki ke hoʻohana ʻia nā mea hoʻololi he nui. palena i ka hana o ka mīkini wiliwili laser aunoa. I kēia lā, ke nānā aku nei mākou i ka mīkini welding laser manual, no laila e hoʻoponopono maoli ka mīkini lima i nā pilikia i luna. ʻO kāna hana hoʻoheheʻe ʻana ʻo ka hana ʻana i ka hana kuʻi ʻana ma ka hui pū ʻana o ka laser paʻa lima me nā kihi mana like ʻole, no laila hiki ke ʻōlelo ʻia he mea hana laser maʻamau ʻole e hoʻololi i ka hoʻopili ʻana o nā ʻano a me nā kihi o nā huahana. ʻOiai ke kiʻekiʻe o ka mana, hiki iā ia ke hoʻololi i ka welding o ka hapa nui o nā huahana

ʻOi aku ka haʻahaʻa o ka huahana o nā mīkini wiliwī laser manual ma mua o nā mea hana piha. Eia nō naʻe, no ka hoʻoili decentralized a i ʻole ka hana nui ʻole a me ka hoʻopili ʻana i nā mea kanu hana, ʻoi aku ka maikaʻi o ka welding laser manual. ʻAʻole pono e hoʻonohonoho i kahi papaʻaina welding a pale i ka pilikia o ka papahele papahele nui. Eia kekahi, wiliwili nā hale hana liʻiliʻi i nā ʻano huahana like ʻole me nā ʻano like ʻole, no laila hiki i ka welding laser manual ke hoʻokō piha i nā pono o ia hana a loaʻa iā ia kahi kūpono kūpono.

Kuʻi lima laser me ka pololei ʻole o ka papaʻaina kuʻi, ka hoʻohana haʻahaʻa o nā mea hoʻopau a me ke kumukūʻai mālama haʻahaʻa o nā lako. ʻO ka ʻōlelo maʻamau, pono mākou e mālama i nā papa hana ʻoi aku ka nui, ʻoiai hiki i nā mea hana laser manual ke hoʻopau i ka hana inā lōʻihi ia i lako me nā hui wili laser portable. Maʻalahi e hoʻololi, haʻahaʻa ke kumu kūʻai o nā ʻāpana pani. Inā ʻaʻole ʻoe ʻike pehea e hoʻololi ai iā lākou, hiki iā ʻoe ke hāʻawi iā lākou i ka mea hana no ka mālama pono ʻana me ka hopohopo ʻole no ka hoʻouna ʻana.

Hoʻokaʻawale ʻia ka ʻokoʻa ma waena o nā mīkini welding laser a me nā mīkini wili laser manual. Manaʻo paha ka poʻe he ʻoi aku ka maikaʻi o ka welder laser ma muli o ka maʻalahi, akā ʻo ka ʻoiaʻiʻo, ua hoʻohana ʻia nā ʻano mea ʻelua no nā kumu like ʻole a ua loaʻa i kēlā me kēia me kona pono ponoʻī. Ma ke kaʻina hana koho, pono mākou e koho i nā mea hana wili laser kūpono no kā mākou hana e like me kā mākou pono maoli.

Ka manawa hoʻouna: Feb-01-2023